Laser Marking & Engraving Machines

Our Meta range will fit most requirements, from the ultra-compact desktop nMeta, to our high-performance Meta-C systems (3D as standard).

About

3D printing has become an integral part of manufacturing, allowing for smarter manufacturing in automotive, aerospace, defence and energy sectors. Onyx® Is one of the strongest materials that can be used in 3D printing and can be marked using a UV laser system.

applications

Onyx is made using carbon fibre and nylon to create a reinforced material which is considered to be the perfect 3D printing material.

When compared to other materials that are used in 3D printing, Black Onyx® is shown to have higher flexural resistance as well as a higher heat deflection temperature making it the ideal to be used in sectors that require strong components, such as the automotive industry and defence sector.

For a long time 3D printing was not considered to be viable in general manufacturing as it introduced many hurdles that needed to be overcome to create strong usable parts. Slow creation time, potential errors when printing and the lack of strength in the products produced meant that many manufacturers were sticking to traditional methods rather than introducing 3D printing to their systems. Overtime however these problem have been solved leading to a new method of manufacturing which allows for higher levels of precision as well as unique possibilities to solve unique problems, this is known as smart manufacturing.

Within the Automotive and aerospace industries 3D printing has allowed for the creation of parts that allow for additional safety as well as unique parts that would be difficult to produce using traditional methods. In recent years we have seen Onyx® being used in aircrafts, motorsports and machinery with many companies seeing 3D printing as a method to produce parts that previously would not have been possible or would have been too expensive to produce/purchase.

The Process

With most laser machines the answer is no, however it is possible with a UV laser.

UV laser systems are perfect for marking delicate materials. Commonly used on glass and crystal, UV lasers use what is known as “cold processing”, this is where the laser uses high energy photons on the ultraviolet spectrum to break the chemical bonds in the material through a cold reaction, therefore making a mark on the material.

As this process generates no heat it is perfect for delicate materials which would usually sustain thermal damage from fiber and CO2 lasers. This is why the use of 3D printing onyx® and marking it with a UV laser system is the perfect combination in modern day smart manufacturing.

3D printing allows for the creation of unique highly detailed parts, however it is not possible to create parts with intricate markings with the 3D printer alone, this is where a UV laser system comes in. Being able to mark Onyx® with high precision, allowing for QR codes, part numbers and other critical markings to be added to the material without damaging the part in any way.

technology

Although Onyx® is one of the strongest materials you can use for 3D printing it is still susceptible to thermal damage from CO2 and Fiber lasers, therefore a UV laser is required to mark onto this material.

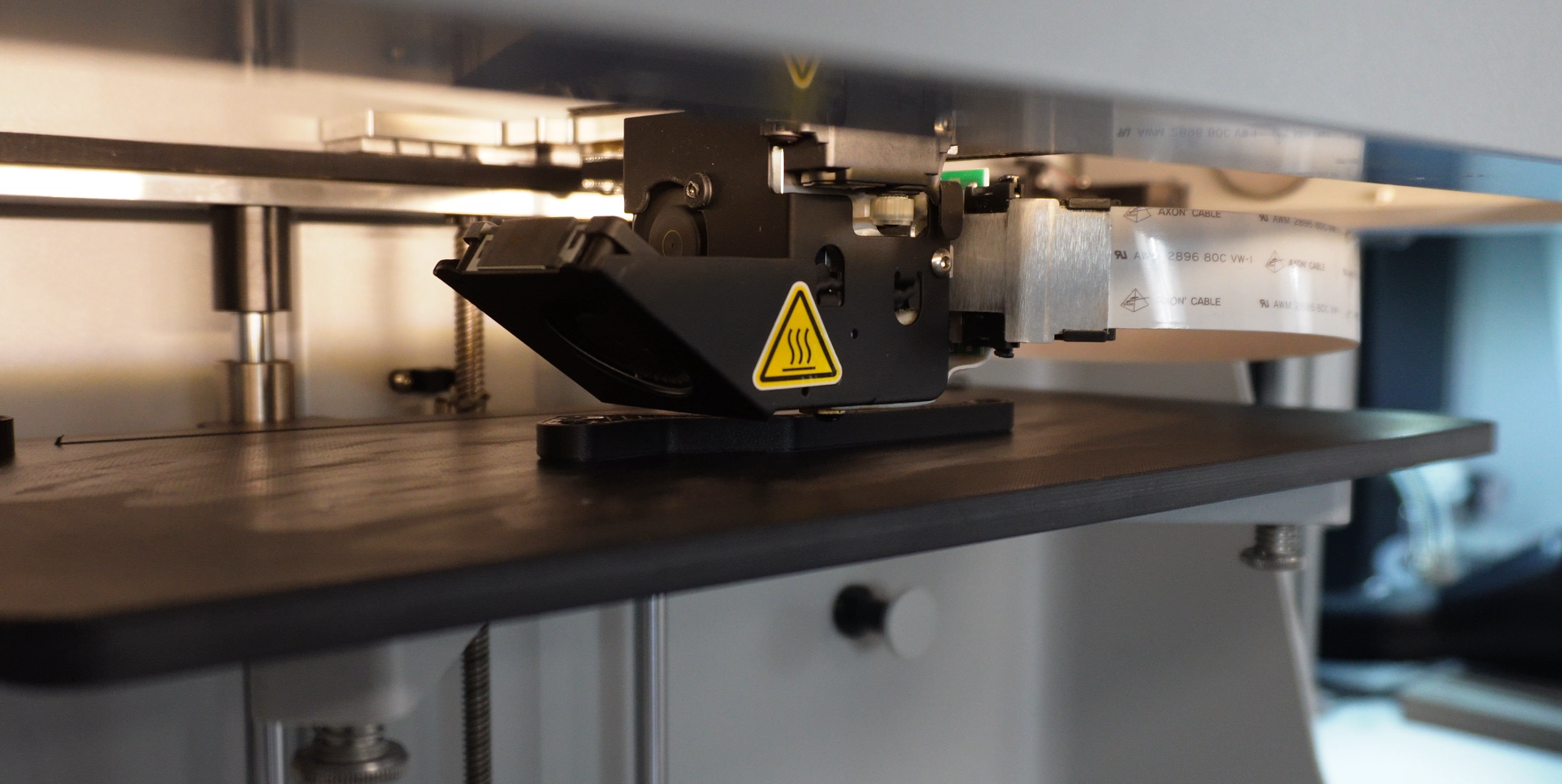

Machine

Due to the damage that can be caused from using a CO2 or Fiber laser on this material the Meta-C UV is the laser we system we recommend for marking Onyx® and other similar 3D printed material.

Trusted and loved by thousands of businesses