* General guide only, there are many crossovers and caveats, please contact us for more details.

About

Laser Cutting Fabric

In the world of fabric crafting and design, innovation knows no bounds. One such ground-breaking technology that has transformed the way fabrics are cut and designed is laser cutting. While scissors and rotary cutters have long been the staples of fabric cutting, laser cutting fabric has emerged as a precise, efficient, and versatile alternative…

Laser types

Choosing the Right Wavelength

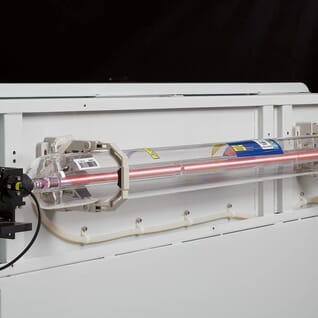

Laser cutting involves the use of a focused laser beam to precisely cut through materials, including fabrics. The choice of laser wavelength is crucial for effective cutting. In the context of fabrics, CO2 lasers with the wavelengths around 10.6µn (10,600nm) are commonly used. This wavelength is well-suited for cutting through various fabrics, as it is efficiently absorbed by organic materials like cotton, wool, silk, and synthetic fibers.

The laser’s energy is absorbed by the material, causing it to heat up rapidly and vaporise. This process, known as ablation, results in clean and precise cuts with virtually no significant fraying or distortion around the edges as the heat generated during the laser cutting process can melt the fibers of the material to form a heat sealed edge. By selecting the appropriate laser wavelength, fabric artists and manufacturers can achieve intricate and flawless designs.

Advantages

Benefits of Laser Cutting Fabric

Laser cutting has undeniably transformed the world of fabric crafting and design. With the right laser wavelength, it offers unmatched precision, versatility, and efficiency. This technology has not only expanded creative possibilities for designers but has also optimised manufacturing processes and reduced waste.

Precision

Laser cutting offers unparalleled precision, allowing intricate and complex designs to be cut with exceptional accuracy. This is particularly advantageous for detailed patterns and delicate fabrics.

Versatility

Laser cutting is versatile and can be used on a wide range of fabrics, from lightweight sheers to heavy textiles. This adaptability makes it a preferred choice for both fashion and interior design applications.

Minimal Waste

Traditional cutting methods often lead to material wastage due to inaccurate cuts and overlaps. Laser cutting minimises waste by following precise digital designs, optimising material utilisation.

Sealed Edges

The heat generated during laser cutting seals the edges of the fabric as it cuts, reducing fraying and eliminating the need for additional finishing steps.

Time Efficiency

Laser cutting automates the cutting process, significantly reducing the time required to create intricate designs. This can be a game-changer for large-scale production.

Intricate Designs

Laser cutting allows for the creation of intricate and complex patterns that would be challenging to achieve using traditional methods. This has led to innovative design possibilities in fashion, costumes, and textiles.

typical applications

Laser Cutting Fabric

Fashion Industry

Laser cutting has injected new life into the fashion industry, enabling designers to experiment with intricate lace patterns, unique cutouts, and innovative textures. It has also facilitated the production of ready-to-wear garments with consistent quality.

Home Textiles

In home decor, laser-cut fabrics find applications in curtains, drapes, upholstery, and decorative elements.

Costume Design

Whether for theatrical performances, cosplay, or special events, laser-cut fabric is invaluable in creating intricate and attention-grabbing costumes.

Automotive Interiors

Fabric laser cutting is used in the automotive industry for creating custom upholstery, seat covers, and interior accents, enhancing both aesthetics and comfort.

Technical Textiles

Laser cutting finds its place in producing technical textiles used in medical products, sportswear, and industrial applications, where precision and durability are paramount.

MACHINE

Recommendations

From intricate fashion designs to functional technical textiles, the applications of laser-cut fabric are vast and continue to shape the future of fabric-based innovation. So, whether you’re a designer pushing the boundaries of fashion or a fabric enthusiast exploring new horizons, laser cutting is a tool that’s worth embracing. Get in touch today to find the best machine for your laser cutting fabric needs.

Trusted and loved by thousands of businesses, including: