* General guide only, there are many crossovers and caveats, please contact us for more details.

About

Laser Marking Machine for Gold

In the ever-evolving world of gold jewellery crafting, technological advancements have played a pivotal role in enhancing precision and creativity. One such cutting-edge tool that has revolutionised the industry is the laser marking machine for gold jewellery. Let’s explore the significant benefits of laser marking machines, along with the best laser wavelength for this particular application…

Precious Metal

The Properties of Gold

Gold possesses unique physical and chemical properties that make it an ideal material for jewellery crafting. Some key properties of gold include…

Malleability and Ductility

Gold is highly malleable and ductile, allowing craftsmen to shape it into intricate designs and delicate filigree work.

Non-Reactivity

Gold is highly resistant to corrosion and tarnishing, ensuring its longevity and enduring beauty over time.

Softness

While gold’s softness enhances its malleability, it also means that it can be susceptible to scratches and wear. Laser marking offers a contactless solution to avoid any physical damage to the delicate gold surface.

.

Get in touchadvantages

Laser Marking Machine for Gold Jewellery

Precision and Detailing

Laser marking machines offer unrivalled precision, enabling artisans to create intricate designs and personalised engravings with incredible accuracy.

Versatility

Laser marking machines can be used on various gold jewellery pieces, including rings, necklaces, bracelets, and earrings. This versatility allows craftsmen to explore their creativity without limitations.

Non-Contact Process

Laser marking is a non-contact process, minimising the risk of damage to the gold surface and ensuring a flawless mark without distortion.

Efficiency and Productivity

Laser marking machines provide high-speed marking, enhancing production efficiency and reducing manufacturing time, ultimately leading to increased productivity.

Eco-friendly Solution

Laser marking is a greener alternative compared to traditional chemical etching methods. It produces minimal waste and doesn’t involve the use of hazardous chemicals, contributing to a more sustainable jewellery crafting process.

SOLUTIONS

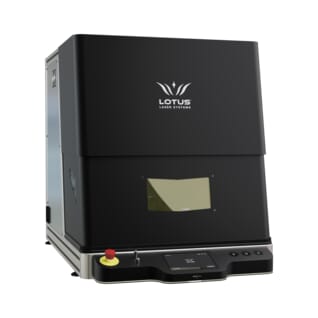

Laser Marking Machine for Gold Jewellery

Whatever the size of your business, we’ve got the perfect laser marking machine for gold jewellery. From the compact nMeta that fits seamlessly into your retail space, to the robust Meta-C Fiber, our lasers come with a host of features that make engraving gold jewellery quick and easy. Use the precision camera to see exactly where you’re marking on those precious metals or attach a rotary device to engrave around the circumference of rings. The possibilities are endless.

FLEXIBILITY

The Best Laser Wavelength for Gold Jewellery Marking

The selection of the appropriate laser wavelength is crucial to achieve optimal results when marking gold jewellery. The two most common laser types used in jewellery marking are Fiber lasers and UV lasers. Each has its unique characteristics and applications.

Fiber lasers are well-suited for marking metals, including gold. They create deep, contrasting engravings and annealing marks, producing a black finish on the gold surface. This is ideal for adding serial numbers, logos, or inscriptions with lasting visibility.

UV lasers are excellent for surface marking and shallow engravings on gold. The short wavelength allows for fine detailing and precision, making it perfect for intricate surface ornamentation and delicate designs.

Jewellery Engraving

Videos

-

Meta C 60w Fiber laser engraving green powder coated bottle

-

Meta C 60w Mopa Fiber laser engraving automotive part

-

Meta C 75w CO2 laser engraving powder coated bottles

-

Meta C 75w CO2 laser engraving a ceramic mug

-

Meta C 60w MOPA fiber laser engraving tools on 1 2m conveyor feed

-

uMeta laser engraving the inside of rings

-

uMeta laser marking a high quality photo to a keychain

-

Meta C MOPA fiber laser marking plastics

-

uMeta laser engraving steel and aluminium with some depth

Trusted and loved by thousands of businesses, including: