* General guide only, there are many crossovers and caveats, please contact us for more details.

About

Cutting and Laser Engraving Silicone

Silicone, a versatile material that has revolutionised countless industries, is known for its unique properties and wide range of applications. From the medical field to construction, electronics to personal care, silicone has become an indispensable material due to its exceptional characteristics and versatility. Let’s delve into this unique material’s properties and find out how laser cutting and laser engraving silicone has transformed a wide range of sectors…

Key Characteristics

Properties of Silicone

Silicone is a synthetic polymer composed of silicon, oxygen, carbon, and hydrogen atoms. Its molecular structure gives silicone its distinctive properties, making it stand out among other materials. Let’s explore some of its key characteristics…

Temperature Resistance

Silicone exhibits excellent thermal stability and can withstand extreme temperature ranges. It remains flexible and functional in temperatures ranging from -100°C to 300°C, making it ideal for applications requiring high or low-temperature resistance.

Flexibility and Elasticity

Silicone is highly flexible and elastic, allowing it to be easily moulded into various shapes and sizes. This property makes it suitable for applications requiring stretchability, such as medical devices and gaskets.

Biocompatibility

Medical and healthcare industries benefit greatly from silicone’s biocompatible nature. It is non-toxic and does not cause allergic reactions, making it suitable for medical implants, prosthetics, and wearable medical devices.

Cutting & Engraving

The Process

Laser engraving silicone involves using a high-powered laser beam to remove a thin layer of the silicone material. The laser’s heat causes localised melting and vaporisation, resulting in precise and permanent etchings. This process enables the creation of intricate designs, text, and even 3D effects on silicone surfaces.

Laser cutting silicone involves using a high-powered laser beam to create precise cuts on silicone sheets, moulds, or 3D objects. The laser beam melts and vaporises the silicone along the cutting path, resulting in clean and accurate edges.

Typical Uses

Cutting and Laser Engraving Silicone

Promotional and Branding Products

Laser-engraved silicone wristbands, keychains, and phone cases offer an innovative way to showcase logos, slogans, or personalised messages for promotional and branding purposes.

Medical and Healthcare Devices

Silicone is widely used in the medical field due to its biocompatibility. Laser engraving allows for the precise marking of medical devices, such as catheters, implants, and surgical instruments, ensuring accurate identification and traceability.

Fashion and Accessories

Laser-engraved silicone bracelets, watch straps, and jewellery offer a unique and stylish appeal. Intricate patterns, names, or symbols can be engraved, making each piece one-of-a-kind.

Industrial Applications

Laser engraving on silicone is employed in industries where silicone components require identification or branding. It provides clear and permanent markings on silicone seals, gaskets, and connectors, aiding in product recognition and quality control. Furthermore, laser cutting is also commonly used in industries where silicone components require precise and accurate cutting. This includes gaskets, seals, O-rings, and custom-shaped silicone parts used in machinery, electronics, and automotive applications.

the benefits

Cutting and Laser Engraving Silicone

Durability

Silicone is known for its resilience and resistance to wear and tear. Laser engraving adds a durable and long-lasting dimension to silicone products without compromising their inherent properties.

Precision and Detail

Laser engraving allows for incredibly fine details and intricate patterns. The laser beam can achieve precise cuts and engravings, enabling the reproduction of complex designs accurately.

Customisation

Laser engraving on silicone opens up a world of customisation. Whether it’s personalised gifts, promotional items, or branding materials, laser-engraved silicone products offer a unique touch that sets them apart.

Non-toxic and Safe

Laser engraving on silicone is a non-toxic process, as it does not require the use of additional chemicals or inks. This makes it safe for various applications, including medical devices, food-grade products, and children’s items.

Clean and Sealed Edges

Laser cutting on silicone produces clean edges without the need for additional finishing processes. The heat from the laser melts the silicone, sealing the edges and preventing fraying or unravelling.

Speed and Efficiency

Laser cutting is a fast and efficient process, especially for cutting intricate designs. It eliminates the need for manual cutting or using traditional cutting tools, saving time and increasing productivity.

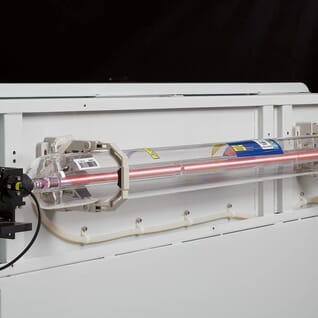

MACHINE

Recommendations

At Lotus Laser Systems we manufacture a wide range laser marking and engraving solutions ideally configured for laser cutting and laser engraving silicone. From UV to CO2, our experts would be happy to recommend which configuration best suits your application.

Trusted and loved by thousands of businesses, including: