* General guide only, there are many crossovers and caveats, please contact us for more details.

About

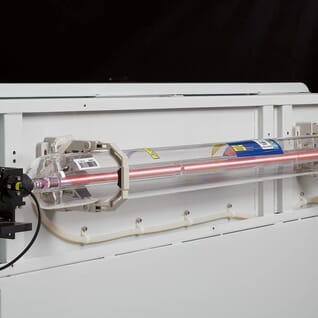

Perspex Laser Cutter

In the world of modern design and fabrication, precision and versatility are of the utmost importance. One technology that has revolutionised the way modern manufacturers work with materials like Perspex is the laser cutter. Offering incredible accuracy and high speeds, a Perspex laser cutter is in a league of its own when you compare it to traditional cutting methods. Let’s take a look at how laser technology outshines its conventional counterparts…

Applications

Understanding Perspex and its Appeal

Perspex, also known as acrylic or plexiglass, is a transparent thermoplastic that has gained popularity due to its versatility, lightweight nature, and ease of manipulation. Its applications span across industries, including signage, architectural models, jewellery, crafts, and even medical devices. However, working with Perspex requires precision and a fine touch, which is where laser cutting technology shines.

Modern Technology

The Laser Advantage

Unparalleled Precision

Laser cutters use focused beams of light to cut through materials, allowing for incredibly precise cuts. This is particularly important when working with Perspex, where intricate designs and details matter.

Minimal Material Wastage

Traditional cutting methods often result in a significant amount of material wastage due to the width of the cutting tool or the heat generated during the process. Laser cutters, however, minimise wastage and maximise throughput.

Intricate Designs

Laser cutters can create intricate and complex designs that would be practically impossible or very time-consuming to achieve with traditional methods. This is a huge advantage when crafting items like jewellery, architectural models, or decorative pieces.

Speed and Efficiency

Laser cutting is exceptionally fast, making it ideal for both small-scale projects and large production runs. The speed of laser cutting allows for rapid prototyping and streamlined manufacturing processes.

Clean and Smooth Edges

Laser cutting produces clean and polished edges, eliminating the need for additional finishing work. This is especially crucial when working with transparent materials like Perspex, where any imperfections are readily visible.

Perspex Laser Cutter Applications

Signage and Displays

A Perspex laser cutter can be a particularly useful tool for manufacturing signage and displays. Perspex is widely used in creating signage for businesses, events, and exhibitions. The precision of laser cutting ensures that intricate logos, fonts, and designs are accurately replicated.

Prototyping and Model Making

Architects and designers often utilise laser-cut Perspex to create scaled-down architectural models or prototypes. The precision of the laser cutter ensures that all details are accurately represented.

Art and Crafts

Laser-cut Perspex opens up endless possibilities for artists and crafters. It can be used to create intricate jewellery, ornaments, stencils, and decorations.

Enclosures and Casings

In industries such as electronics and manufacturing, Perspex enclosures and casings are a popular choice due to their transparency and durability. Laser cutting ensures precise openings and a snug fit for components.

MACHINE

Recommendations

Whether you’re crafting signage displays or constructing intricate architectural models, a Perspex laser cutter allows you to achieve remarkable results that were once thought to be unattainable with traditional cutting methods. At Lotus Laser Systems we manufacture a wide range of laser solutions ideally configured for laser cutting Perspex. Get in touch today, our experts would be happy to recommend which configuration best suits your application.

Trusted and loved by thousands of businesses, including:

Examples

Fiber Laser Videos

-

Meta C 60w Fiber laser engraving green powder coated bottle

-

Meta C 60w Mopa Fiber laser engraving automotive part

-

Meta C 75w CO2 laser engraving powder coated bottles

-

Meta C 75w CO2 laser engraving a ceramic mug

-

Meta C 60w MOPA fiber laser engraving tools on 1 2m conveyor feed

-

uMeta laser engraving the inside of rings

-

uMeta laser marking a high quality photo to a keychain

-

Meta C MOPA fiber laser marking plastics

-

uMeta laser engraving steel and aluminium with some depth