* General guide only, there are many crossovers and caveats, please contact us for more details.

PRODUCT LIFECYCLE

Laser Coding for Traceability

Traceability helps to optimise production lines and is used in a range of industries including automotive, aviation and medical. So what exactly is traceability marking and why is laser coding technology changing the industry? Let’s find out…

PRODUCTION LINES

What is Traceability Marking?

At its most basic, traceability is the ability to track and trace products throughout the manufacturing process through serial numbers, barcodes and QR codes, to name a few. Traceability has become an essential part of global trade and is especially important in industries that use components from a variety of subcontractors.

It enables businesses to trace all processes during production, to determine when and where an item was produced and to find historical information on raw materials, manufacturing details and distributors.

Get in touchLEGALITIES

Safe Environments

A laser engraving or laser cutting machine is a big investment and finding a safe, affordable solution for employees isn’t always easy.

P601 Certified Installation

Under HSE’s Control of Substances Hazardous to Health (COSHH) Regulations, Local Exhaust Ventilation (LEV) testing is a legal requirement in the UK. Your equipment must be thoroughly examined and tested by a competent person at least every 14 months to ensure your employees are safe.

Our systems are installed by a P601 certified engineer and we fit certified filtration systems. You may be breaking the law if you simply vent your laser through a window, it must be adequately filtered before any particulates and gases are vented back into the atmosphere. You can find out more on the HSE website.

CE Certified

CE marking indicates that a product has been assessed by the manufacturer and deemed to meet EU safety, health and environmental protection requirements. It is required for products manufactured anywhere in the world that are then marketed in the EU.

Sadly, there are a great deal of companies that provide laser solutions to end users which do not carry the CE mark. Furthermore, there are many imported and low cost “Class 4” (open laser) style products flooding the EU market, even being sold by major retailers. These can be extremely dangerous if the user is not qualified and properly protected.

PRODUCT CODING

Why is Traceability Marking Important?

The benefits of traceability marking are plentiful.

Quality control is one of the main advantages of traceability, it reduces the chance of lower-quality materials being used by a supplier if you monitor and trace the production process. Traceability can also reduce the negative impact of product recalls. By knowing exactly which products are defective and locating where they are efficiently, costly implications of recalls can be avoided.

Most importantly, it allows manufacturers to determine exactly when and where problems in the supply chain occur, helps to resolve inefficiencies, and ultimately saves the business money.

SUPPLY CHAIN

External Traceability

Also known as chain traceability, this is the ability to track products through an entire supply chain. From procurement of raw materials to the finished product, external traceability means manufacturers can trace forward to where their products have been delivered and those downstream in the chain are able to trace the origins of the products.

During production, a single item can move through many different manufacturers so ensuring it is clearly traceable throughout each part of the process is vital for quality control amongst other things.

ISO9001

Internal Traceability

Internal traceability is different to external in that its limited to a specific area in an entire supply chain, such as a single company or department. For example, in a single company internal traceability may include tracking the item from arrival, logging manufacturing information and then logging shipment.

For external traceability to work successfully, each individual company in a supply chain must implement their own internal traceability system

THE WAY FORWARD

Laser Coding

For years Continuous Ink Jet printing (CIJ) has dominated the industrial sector for coding applications, but laser marking is fast replacing this technology.

When traceability marking is mandatory in the manufacturing process, parts are scrapped if codes aren’t legible. Manufacturing parts are often subject to harsh conditions over their lifetime and outdated systems such as CIJ printing, dot peen or other non-permanent marking methods can become defaced over time. Laser coding offers a permanent marking solution and the best readability rates, resulting in less product wastage and a higher return on investment.

Keeping up-to-date

The Benefits of Laser Traceability Marking

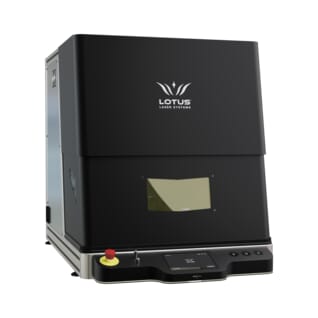

Laser technology is ideal for traceability marking because it is permanent and difficult to counterfeit. It can produce a wide variety of graphic formats, from logos and barcodes to simple text and it has no consumables, so running costs are low as is the requirement for maintenance. Furthermore, marking with a laser is contactless so the process is quick and cost-effective.

Better for business, a laser marker is easy to integrate into production lines thanks to the size of the machines and the beam deflection unit (sometimes known as the scan head) can be placed several hundred millimetres away from the product being marked.

In short, when compared to other traceability marking methods, laser markers provide a permanent, high-quality solution that’s hard to beat.

RELATED

Example Applications

Laser Engraving Photos to Wood

All natural timbers and most engineered wooden boards can be laser engraved by a CO2...

Oct

Trusted and loved by thousands of businesses, including: