* General guide only, there are many crossovers and caveats, please contact us for more details.

Production & Manufacturing

Automotive Laser Marking

The advantages of using laser technology in automotive production are plentiful. From initial design to the final assembly of the vehicle, laser technology can be employed throughout the entire automotive production process. Whether it’s textile cutting for seatbelts or marking parts for traceability, let’s find out how lasers are used in the automotive industry today…

Mark, Cut, Engrave

Versatile & Reliable

Endlessly versatile, laser systems can cut, mark, etch and/or engrave a range of materials, making it an invaluable technology for a cutting-edge industry. From plastics, metals and glass to textiles and rubber, the automotive sector utilises a plethora of materials during production, all of which can be modified by laser technology.

Automotive Laser Marking

Lasers are used on many car parts

From tracking critical components through traceability to marking plastic parts for dashboard panels, let’s take a look at how the automotive sector is utilising laser technology today…

Technology First

Automotive Laser Marking

In today’s world, the manufacturing of vehicles is largely automatic. Robots have been routinely used in the industry for many years and now manufacturers are utilising laser systems in line with this technology to further streamline the process. This automated way of manufacturing means it’s imperative that the laser machines can be easily integrated into production lines.

An automotive laser marking machine is easy to integrate into manufacturing lines thanks to the relatively small size of the systems. Furthermore, the beam deflection unit (sometimes known as the scan head) can be placed several hundred millimetres away from the product being marked. Thanks to it being a non-contact method of marking, there’s no need for parts to be clamped down before marking, avoiding unnecessary secondary damage, and further increasing productivity and efficiency.

Production

Traceability Marking

The automotive industry is heavily reliant on traceability for success. In an industry where a large number of components come from different suppliers, it’s imperative that every part can be traced back to the manufacturer to avoid costly scrap material. Laser technology is ideal for traceability marking because it is permanent and difficult to counterfeit. It can produce a wide variety of graphic formats, from logos and barcodes to simple text and it has no consumables, so running costs are low as is the requirement for maintenance.

legalities

Vehicle Identification Number

Every vehicle registered in the UK must have a unique Vehicle Identification Number (VIN). This 17-character VIN is usually stamped in the chassis of the vehicle and serves as the car’s unique identity code before it even leaves the production line. Laser marking is a consistent and reliable way to brand vehicles with a VIN, ensuring legibility for the lifetime of the vehicle.

Automotive Sector

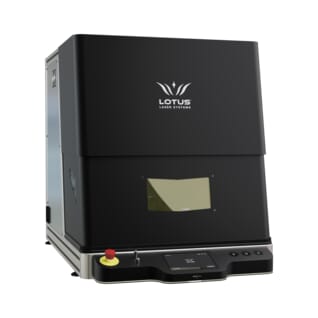

Suitable Machines

Whether it’s marking Vehicle Identification Numbers or data matrix codes, we have the right laser machine to meet your automotive sector needs. From steel ball bearings to plastic housing, when it comes to the laser engraving of automotive parts, our machines are designed to do it all.

Trusted and loved by thousands of businesses, including: