* General guide only, there are many crossovers and caveats, please contact us for more details.

Healthcare Sector

Medical Laser Marking

Laser marking has revolutionised the medical sector. Used across the industry from the production of surgical equipment to UDI traceability marking, here’s how laser technology is being utilised in the healthcare industry today…

fda requirements

Patient Safety

To ensure patient safety the healthcare industry requires a high level of traceability across all medical devices.

In the USA, the FDA (Food and Drug Administration) recently introduced the UDI directive which requires all medical devices to be labelled with a unique device identification as standard. This means if a device is intended for more than one use, the UDI must be marked directly onto the device itself, not only on labels and packaging which is separated from the device after the first use.

Currently in the UK, although the UK Medical Device Regulations 2002 do not provide a legal obligation to do so, many manufacturers already implement the addition of UDIs on their medical devices as a matter of best practice.

The unique device identification system introduced by the FDA improves patient safety and allows products to be traced back directly to the manufacturer if required, for example in the case of a product recall.

LEGALITIES

Medical Laser Marking & Traceability

Laser technology is ideal for UDI traceability marking because it is permanent and clearly legible. It can produce a wide variety of graphic formats, from identification numbers to QR codes and it has no consumables, so running costs are low as is the requirement for maintenance. Furthermore, marking with a laser is contactless so the process is quick, cost-effective and there’s no stress applied onto the materials. When marked with a laser, UDIs are legible long into the future and can withstand the rigours of regular sterilisation without risk of fading.

A laser engraving or laser cutting machine is a big investment and finding a safe, affordable solution isn’t always easy. When it comes to medical laser marking, quality control is of the utmost importance and meeting health and safety requirements is essential.

P601 Certified Installation

Under HSE’s Control of Substances Hazardous to Health (COSHH) Regulations, Local Exhaust Ventilation (LEV) testing is a legal requirement in the UK. Your equipment must be thoroughly examined and tested by a competent person at least every 14 months to ensure your employees are safe.

Our systems are installed by a P601 certified engineer and we fit certified filtration systems. You may be breaking the law if you simply vent your laser through a window, it must be adequately filtered before any particulates and gases are vented back into the atmosphere. You can find out more on the HSE website.

CE Certified

CE marking indicates that a product has been assessed by the manufacturer and deemed to meet EU safety, health and environmental protection requirements. It is required for products manufactured anywhere in the world that are then marketed in the EU.

Sadly, there are a great deal of companies that provide laser solutions to end users which do not carry the CE mark. Furthermore, there are many imported and low cost “Class 4” (open laser) style products flooding the EU market, even being sold by major retailers. These can be extremely dangerous if the user is not qualified and properly protected.

The Healthcare Industry

Laser Technology & its Place in the Medical Sector

From implantable devices such as a hip balls and bone screws, to high-grade medical instruments; when it comes to laser marking medical devices, the right part must be marked in the right way. Let’s look at how laser technology is being used in the medical sector today…

Sterile Methods

Hygienic Marking

Depending on the wavelength used, the surface texture remains unchanged when it’s marked using a laser. This is an incredibly sterile way of marking because the surface remains smooth, eliminating the chance of bacteria infiltrating the material. This is crucial when dealing with implantable medical devices as no harmful substances are released into the body when marked using a laser.

innovative

No Contact Technology

Thanks to the no contact method of marking, no stress is applied onto a material when marked with a laser. A UV laser source produces significantly less heat than other wavelengths, so much so it’s considered a form of ‘cold marking’. This low heat source is especially important for marking delicate medical tools such as a cannula which can be marked without damage and, most importantly, remains sterilisable once marked.

Accurate & Reliable

Mark with Precision

Some medical tools, such as hypodermic needles, are incredibly small and require a precise marking method. A UV laser source is extremely fine and controlled, making it ideal for the delicate, accurate marking required in this sector.

medical sector

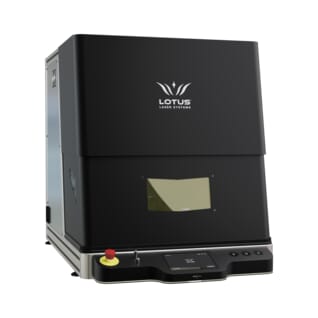

Suitable Machines

Whether it’s for UDI traceability marking or precision marking for medical tools, we have the right laser machine to meet your medical sector needs. From plastic measuring beakers to high-grade stainless steel scalpels, when it comes to the laser engraving of medical instruments, our machines are designed to do it all.

Typical Applications

Stainless Steel

Stainless steel is used widely in the medical sector because it is non-porous and therefore more hygienic in clinical environments. Stainless steel can be sterilised regularly with no risk of corrosion and it can be especially designed for implantable devices to resist biological reactions.

Applications may include pacemakers, hip balls, bone plates, scalpels and surgical dishes.

Plastics

Versatile and affordable, the healthcare industry relies on a range of medical-grade plastics from polypropylene to polyethylene.

Applications may include medical syringes, cannulas, insulin pumps, prosthetics, respiratory equipment, catheters and implants.

Trusted and loved by thousands of businesses, including: