* General guide only, there are many crossovers and caveats, please contact us for more details.

About

Plywood Laser Cutting

In the world of modern fabrication and design, technological advancements have paved the way for innovative manufacturing techniques. One such breakthrough is plywood laser cutting, a process that utilises laser technology to cut intricate and precise designs into plywood sheets. This technique has revolutionised various industries, from architecture and interior design to arts and crafts. Let’s find out more about plywood laser cutting and explore its applications, benefits, and how it has unleashed a world of creative possibilities.

The process

Understanding Plywood Laser Cutting

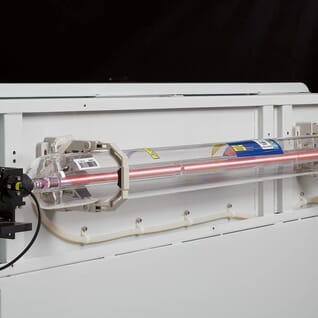

Plywood laser cutting involves using a high-powered laser beam to precisely cut through plywood sheets, resulting in clean and accurate edges. The process relies on the laser’s ability to vaporise or burn the material along a specific path, guided by a computer-controlled design. This digital approach ensures that even the most complex and intricate patterns can be replicated on plywood sheets with unparalleled precision.

Applications

The Versatility of Plywood Laser Cutting

Architecture and Interior Design

Architects and designers can create stunning and intricate patterns for wall panels, screens, room dividers, and decorative elements. The precision and repeatability of the process make it an ideal choice for producing large-scale installations that showcase intricate details.

Furniture Design

Designers can now craft intricate patterns on tables, chairs, cabinets, and other pieces, elevating their aesthetic appeal and adding a touch of uniqueness to each creation. Furthermore, laser-cut plywood parts fit together seamlessly, making assembly efficient and reducing material waste.

Prototyping and Model Making

The precision of plywood laser cutting proves invaluable in prototyping and model making for various industries. From architectural models to product prototypes, the speed and accuracy of the laser-cutting process enable designers to iterate and refine their designs rapidly.

the benefits

Plywood Laser Cutting

Precision and Accuracy

Plywood laser cutting ensures a level of precision and accuracy that is challenging to achieve through traditional cutting methods. This results in clean edges and perfect reproductions of intricate designs.

Time Efficiency

The automation of the cutting process significantly reduces production time. Laser cutting can swiftly manoeuvre through complex designs, making it faster than manual cutting methods.

Minimal Material Waste

Laser cutting minimises material wastage, as it optimises the arrangement of parts on plywood sheets, reducing the amount of scrap material generated.

Design Freedom

Plywood laser cutting provides designers with unparalleled freedom to experiment with intricate and unconventional designs that were previously difficult or impossible to achieve.

MACHINE

Recommendations

Whether you’re an industrial manufacturer or small business we have solutions to help you. Whether you’re looking for a plywood laser cutter or a laser engraving machine, we can find the right system for you and your business.

Trusted and loved by thousands of businesses, including:

Examples

Fiber Laser Videos

-

Meta C 60w Fiber laser engraving green powder coated bottle

-

Meta C 60w Mopa Fiber laser engraving automotive part

-

Meta C 75w CO2 laser engraving powder coated bottles

-

Meta C 75w CO2 laser engraving a ceramic mug

-

Meta C 60w MOPA fiber laser engraving tools on 1 2m conveyor feed

-

uMeta laser engraving the inside of rings

-

uMeta laser marking a high quality photo to a keychain

-

Meta C MOPA fiber laser marking plastics

-

uMeta laser engraving steel and aluminium with some depth