About

Why We Choose Aluminium for our Machines

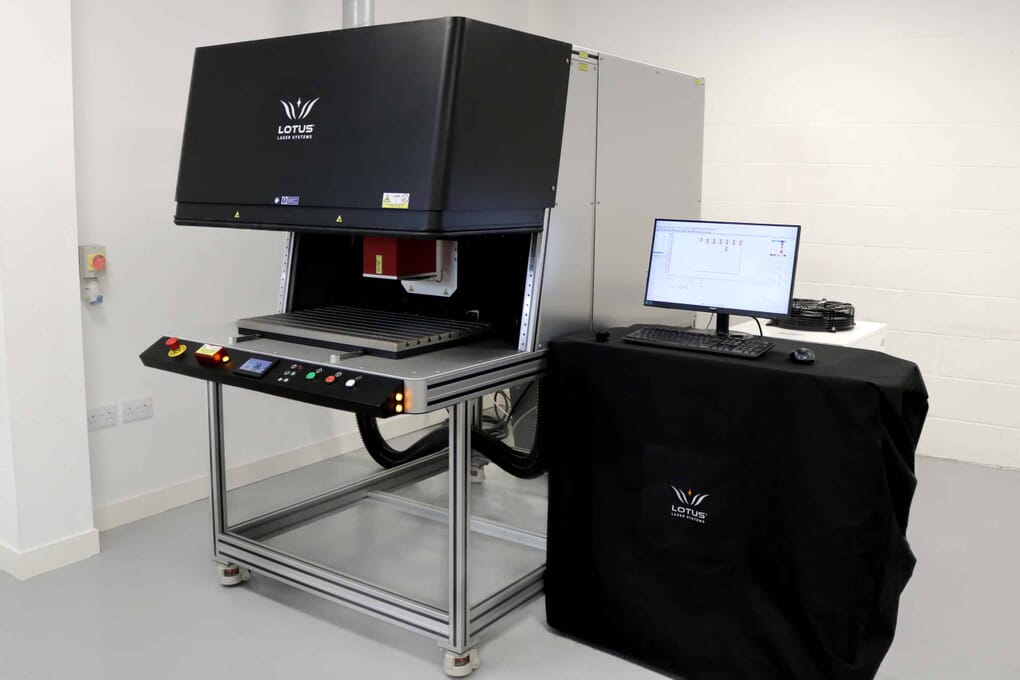

In today’s world, environmental sustainability is at the forefront of technological advancements. Many industries are striving to reduce their environmental impact and adopt eco-friendly practices. At Lotus Laser, we take our commitment to the environment seriously, and one of the ways we demonstrate this commitment is by using aluminium as the primary material for building our laser machines.

The Environmental Impact

Aluminium vs. Steel and Plastic

So why do we choose aluminium over other common materials used in the industry? Let’s take a look at the stand-out reasons…

Aluminium

Recyclability: One of the most compelling reasons we choose aluminium is its exceptional recyclability. Aluminium is 100% recyclable without losing its quality. Recycling aluminium requires only 5% of the energy needed to produce new aluminium. This reduces the demand for new raw materials and significantly lowers greenhouse gas emissions.

Lightweight: Aluminium is much lighter than steel, which reduces the energy required for transportation and lowers the carbon footprint associated with shipping our laser machines.

Durability: Aluminium is known for its corrosion resistance, meaning it lasts longer and requires fewer replacements. This leads to less waste and fewer environmental burdens.

Steel

Resource Intensive: Steel production is energy-intensive and requires large amounts of raw materials, such as iron ore and coal. This results in a significant environmental impact due to the extraction of these resources.

Heavier: Steel is heavier than aluminium, which leads to increased fuel consumption during transportation and higher carbon emissions.

Plastic

Non-Biodegradable: Many plastics used in manufacturing are non-biodegradable and persist in the environment for hundreds of years, causing pollution and harm to wildlife.

Low Durability: Most plastics are not as durable as aluminium or steel, meaning they need frequent replacement, which increases waste.

aluminium

Lotus Laser’s Eco-Friendly Choice

At Lotus Laser, we prioritise sustainability and believe that using aluminium for our laser machines is a responsible choice. By choosing aluminium, we contribute to the reduction of carbon emissions, lower energy consumption, and promote a circular economy. Additionally, aluminium’s lightweight nature and durability enable us to create high-quality machines that require fewer replacements, reducing waste and conserving resources.

It’s worth noting that some laser companies opt for cheaper alternatives, such as plastic or lower-grade materials, to cut costs. While these choices may seem economically advantageous in the short term, they have severe long-term environmental consequences. Cheaper materials often result in higher maintenance and replacement costs, more significant waste production, and a larger carbon footprint.

MACHINE

Recommendations

Lotus Laser is committed to making environmentally responsible choices at every stage of our production process. By choosing aluminium over steel or plastic for our laser machines, we minimise our environmental impact and contribute to a more sustainable future. We believe that the long-term benefits of using aluminium far outweigh any initial cost considerations. Our commitment to the environment goes hand in hand with our dedication to providing high-quality laser machines that meet our customers’ needs while also respecting the planet we all share.

Trusted and loved by thousands of businesses, including: